-Heritage High School Wake Forest, North Carolina-

Engineering III

Contact Mr. Riedel:

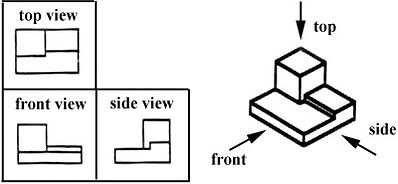

Standard Order of Views

Pictorial Views

Dimensions Line Types

Drawing Interpretation

Drawing Clarity-Setting standards and norms in a drawing for a clear interpretation of the parts and assemblies.

Determine placement of the regular views.

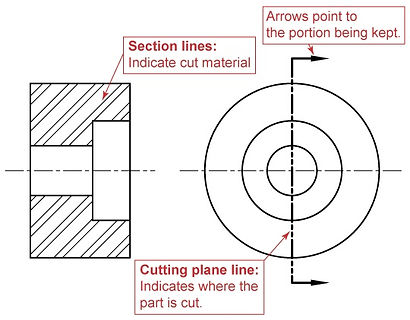

Determine cutting plane lines and corresponding section views.

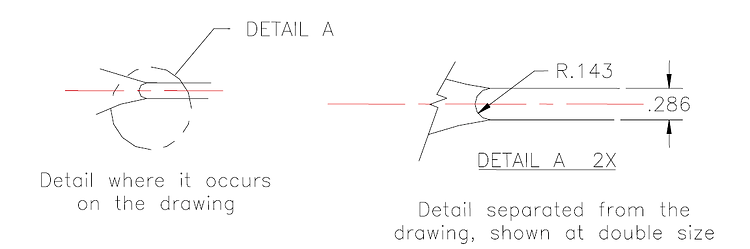

c. Determine detail size and descriptions.

1. Details should be labeled by a phantom line circle on the drawing where they occur.

2. Details can be placed in any convenient space on the drawing. Under the separated detail should be the name and scale of the detail.

Assess you knowledge of Drawing Clarity

Can you identify examples of these line types in a drawing:

- Object lines

- Hidden lines

- Dimmension lines

- Phantom lines

- Section lines

- Center lines

Can you identify the 6 regular drawing views and their location?

Can you identify the 3 commonly used pictorial views?

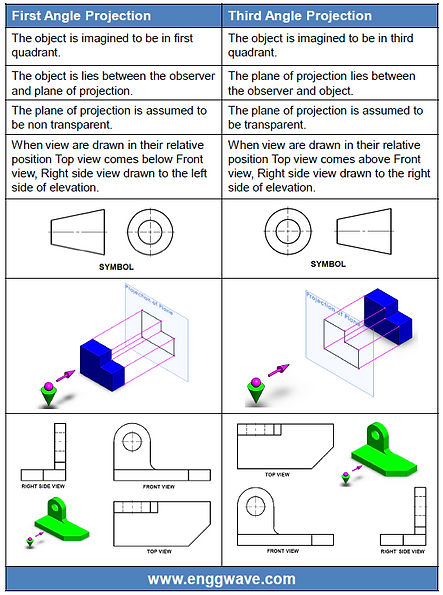

First Angle Projection and Third Angle Projection

Determine the language of the print, and whether it is drawn in first-angle projection or third-angle projection. The standard can be written in the title block or shown as a symbol.

STD-Standard

MACH-Machine

STL-Steel

MAG-Magnesium

SYM-Symmetrical

MATL-Material

TEM-Temper

MAX-Maximum

THD-Thread

MI-Malleable Iron

TOL-Tolerance

MIN-Minimum

TYP-Typical

MISC-Miscellaneous

VAR-Variable

MOD-Modification

VERT-Vertical

NO.-Number

W-Width

NOM-Nominal

WI-Wrought Iron

NTS-Not To Scale

WT-Weight

EST-Estimate

P-Pitch

FAB-Fabricate

PROC-Process

FAO-Finish All Over

QTY-Quantity

FIL-Fillet

QUAL-Quality

FIN-Finish

R-Radius

FORG-Forging

REF-Reference

FST-Forged Steel

REQD-Required

GA-Gage

REV-Revision

GALV-Galvanized

RH-Right Hand

GRD-Grind

RIV-Rivet

GSKT-Gasket

SCH-Schedule

HCS-High Carbon Steel

SCR-Screw

HEX-Hexagon

SECT-Section

HOR-Horizontal

SF-Spotface

HT TR-Heat Treat

SH-Sheet

ID-Inside Diameter

SPEC-Specification

INSTL-Installation

SPL-Special

KWY-Keyway

SQ-Square

LH-Left Hand

SST-Stainless Steel

Commonly UsedDrawing Abreviations

ALLOW-Allowance

ALUM-Aluminum

ALY-Alloy

ANL-Anneal

APPD-Approved

APPROX-Approximate

ASSY-Assembly

AUX-Auxiliary

B/M-Bill of Materials

BEV-Bevel

BRG-Bearing

BRKT-Bracket

BRS-Brass

BRZ-Bronze

BUSH-Bushing

C TO C-Center to Center

C’BORE-Counterbore

C’SINK-Countersink

CDS-Cold Drawn Steel

CH-Case Harden

CHAM-Chamfer

CI-Cast Iron

CL-Clearance

CONC-Concentric

COND-Condition

COP-Copper

CRS-Cold Rolled Steel

CSTG-Casting

CYL-Cylinder

DAT-Datum

DCN-Drawing Change Notice

DIA-Diameter

DWG-Drawing

EA-Each

ECO-Engineering Change Order

ECR-Engineering Change Revision

EQ-Equal

ES-Engineering Specifications

Study Links and Practice Quizzes for Engineering Abbreviations

Quizlet Practice link: https://quizlet.com/join/7jTxDMUKD

Practice your Knowledge of drawing abbreviations by taking this quick quiz: Drawing Abbreviations Practice Quiz